E-BEAM TECHNOLOGY

Introduction

Electron Beam Processing is the method for producing chemical and physical changes in various substances by exposure to ionizing radiation in the form of energetic electrons. Electrons are particles possessing a negative electric charge, which is an integral part of every neutral atom. During this process several different effects may occur depending on the material being processed, the dose or amount of treatment that is being applied. These effects include but are not limited to Cross linking, Polymer Degradation, Sterilization, Pasteurization, and Vulcanization. E-Beam differs from other radiation processes in that it is highly controllable, and can be turned completely off with no residual effects.

E-Beam Applications

- Wires & Cables

- Heat Shrink Products

- PE Foam Matrix

- Molded Products (O-rings, plastic components)

- Rubber Vulcanization (Sheets & Gaskets)

- Degradation of Polytetrafluoroethylene (PTFE)

- Non Polymeric applications like coloring of gems stones, sterilization of medical products, food disinfections etc...

- Treatment of Waste Water or Sludge Cold Pasteurization

Advantages of Electron Beam Irradiation

- Well Efficient to control the Process

- Tighter Tolerances

- Eliminates Limitations in Polymer Compositions, Compounding and Extrusion

- Due to high productivity it helps to reduce the Operating Costs

- Sophisticated design of a machine as compared to Cobalt Gamma Source, which easily turns off and is extremely efficient.

- Better self life

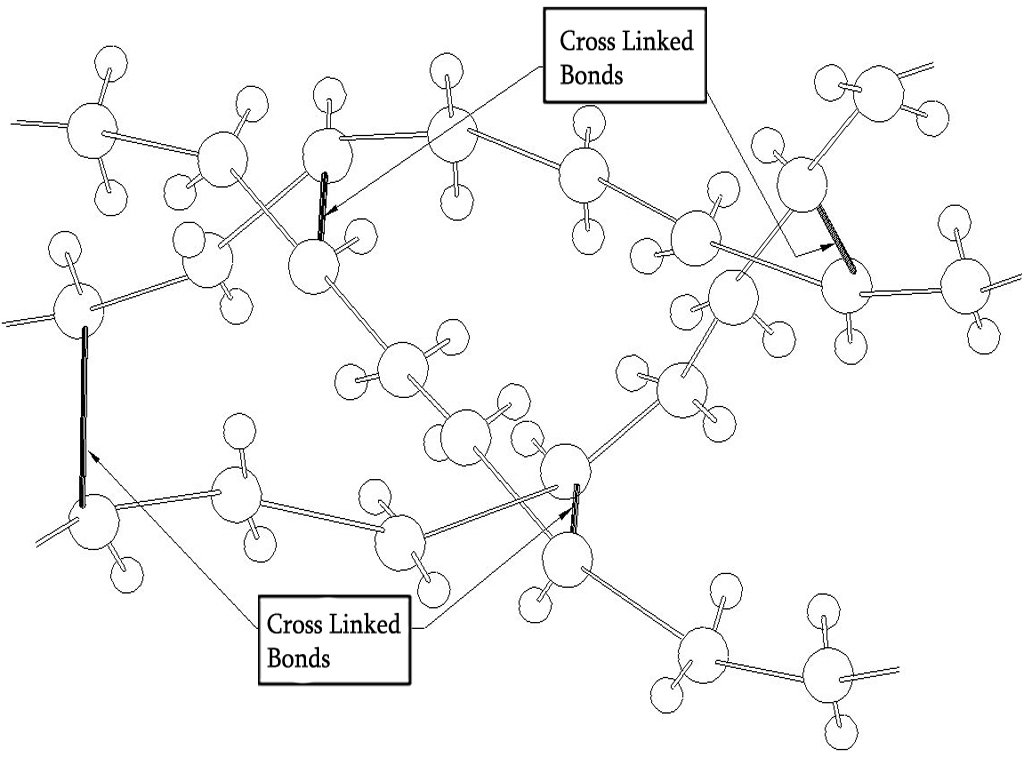

What is Cross linking?

By cross linking, polymer chains are linked together by so-called cross links. A three-dimensional polymer network is created where the molecules have been joined together into a new non melt able polymer system. Now, the polymer chains lose some of their ability to move as individual chains. The result is no melting.

What Cross linking Can Do

Cross linked polymers offer more safety. A “simple PE” with a melting point of around 90°C to 110°C can easily withstand temperatures up to 250°C for several hours without melting—after it has been properly cross linked.

Some of the advantages in relation to more safety and a greener environment include:

- No immediate melting means no immediate short circuits in areas like elevators, large public buildings like schools, theatres, airports, stadiums, ferries and so on.

- Reduced risk of damage by mechanical pressure and cut-through, no short circuits and electrical sparking.

- Improved oil and fluid resistance makes the cables function longer during immersion.

- Improved stress crack resistance keeps electrical circuits and their functioning in place.

- Improved abrasion resistance, which can result in reduced wall thicknesses to save raw materials, space, energy and weight. A lower weight gives an extra premium in terms of lower energy consumption in trains, ships, planes and other transportation systems. What’s more, a lower fuel consumption means lessCO2.

- No dripping in case of fire, less flame spreading, less smoke, less pollution in case of fire.

Cross linking of Polymers by Electron Beam

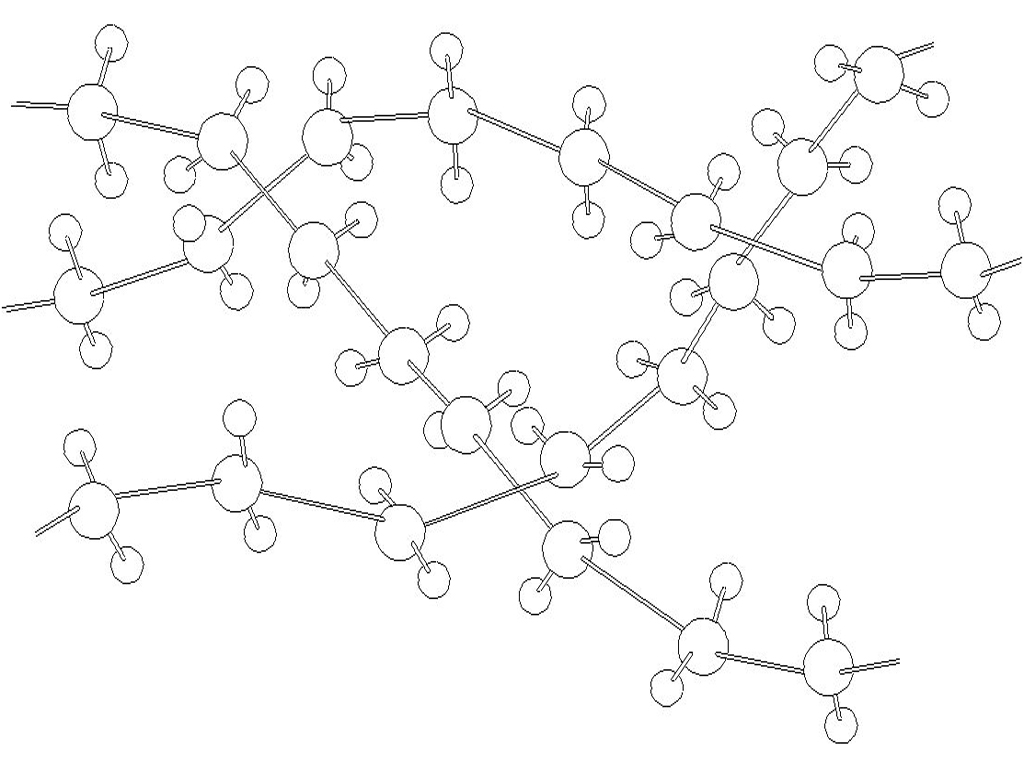

Polymers are long chains of molecules. Each molecule is a specific chemical group. The simplest polymer is polyethylene consisting of a carbon and two hydrogen atoms i.e. CH2 The figure below is a representation of polyethylene.

The chains intermesh in a random manner. Polyethylene is used commonly as plastic food containers. It is tough, flexible and relatively inexpensive.

When heat is applied the chains are free to slip and slide. The polyethylene will soften and melt when heat is applied.

Irradiation cross-linking

provides an alternative method that does not require heat, pressure or moisture and with a wider range of compounds can produce superior products than chemical cross-linking.

Irradiation leaves no unreacted curing agents that can create harmful acids at elevated temperatures. Superior cut and stripping is possible because irradiation cross-linking does not require heat and pressure that can force compound between the wire strands.